How advanced analytics can address agricultural supply chain shocks

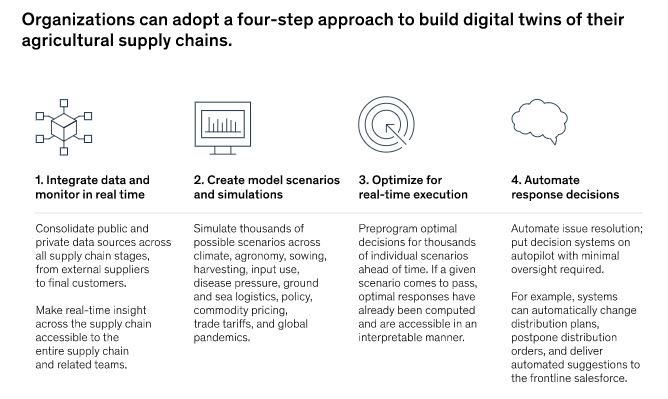

How advanced analytics can address agricultural supply chain shocks: Building automated supply chain planning systems to address global shocks could lead to significant cost savings for agricultural organizations. The COVID-19 pandemic has also intensified supply chain shocks. Farmers around the globe, for instance, lost billions in earnings due to labor shortages, and farmers and agribusinesses suffered economic losses in the first wave of the pandemic due to the closure of trade channels (such as food services), labor shortages, delays in food and raw-material deliveries, and slowdowns in food production caused by virus outbreaks at processing plants. Also in a 3rd world country like Sri Lanka experienced lack of fertilizers to grow their traditional crops. Food processing plants in many countries have also been hard-hit. In addition, extreme weather and the pandemic have caused fertilizer prices to increase, adding to global inflationary pressures. Average 2021 nominal prices of diammonium phosphate and urea, for instance, were about 96 percent higher than their 2019 averages. In turn, increasing fertilizer prices have contributed to global food insecurity, as global food prices in 2021 jumped to their highest level in a decade. The ongoing conflict in Ukraine is further compounding the situation, with the Food and Agriculture Organization of the United Nations stating that the global supply gap from potential shortfalls in agricultural exports from Russia and Ukraine could raise international food and feed prices by more than 20 percent. To respond to agricultural supply chain shocks caused by these kinds of notable events, agricultural companies such as food processors and input providers can consider implementing the next generation of end-to-end supply planning based on a four-step approach. This approach involves the integration of data sources to enable real-time monitoring; simulation to produce various supply chain scenarios; deployment of appropriate optimization algorithms for real-time responses to shocks; and full automation of the first three steps to produce automatic response systems.

Connecting the dots: Automating supply chain decisions across the entire organization: While the level of automation may vary depending on the type of agricultural supply chain, there are prerequisites for operating a technology-driven supply chain planning system that is capable of identifying and driving potential evaluation: • Easily accessible real-time updates. All information on the current status of the supply chain should be accurately reflected in the system, ideally in real time. This requires strong integration of various data feeds and delivery of real-time changes in the appropriate format, including web apps, email updates, and message notifications. • Coordinated execution management. Planning and execution of responses should be coordinated within the planning system; changes to planning and “off the record” transactions or manual bypasses are not considered best practices. • Change management and trust. Company employees must be able to trust the system, and mindsets and behaviors may need to be adapted to promote system use. Relevant initiatives may include training, role modeling, incentives, and implementing rules to prohibit bypassing the system. • Technology capabilities. Streamlined automation of supply chain decision response requires companies to build the right capabilities. These include IT teams capable of both supporting complex systems and working hand in hand with supply chain planners to promote adoption. In addition, data science and engineering talent may be needed to help maintain and fine-tune the advanced analytics functionalities present in these systems. • Rapid error handling. Automated systems should identify and automatically correct deviations from expected values. For example, the system should notify relevant stakeholders if actual purchase order lead times deviate from values agreed upon in contract documents with the supplier, and it should propose potential solutions. • Real-time updates of projections. Automated systems should be able to produce updated projections for supply, demand, and inventory—as well as resulting costs, shortages, and stock levels—at appropriate time intervals. • Prescriptive decision response. The system should have an intelligent engine that can produce optimal recommendations based on trade-offs and can plan for adjustments to deal with problems such as sudden supplier shortages, quality issues at a site, sudden demand spikes, and unexpected orders. We have found that agricultural companies that succeed in implementing these prerequisites in the context of supply chain transformations may capture reductions in supply chain operating costs of up to 15 percent, as well as an increase in overall EBIT of up to 6 percent. Shocks to supply chains from events such as extreme weather, the COVID-19 pandemic, and the invasion of Ukraine have led to billions of dollars of losses across global agricultural supply chains. Building automated planning systems that can handle high levels of uncertainty could potentially lead to improved preparedness against food security risks and higher cost savings for organizations affected by global supply chain shocks.